We are so excited building things for our new abode! Directly across the street is a lovely, wildflower, rabbit, squirrel and bird abundant park. We’ve decided to rid our lives of cable t.v., which affords us way more extra time than I realized, or care to admit. Instead of vegging out to the news upon awakening, we enjoy our morning coffee on the front porch in our super comfy adirondack set that we built with our own hands! We are forced to be more present and enjoy one another and nature more than ever, but the benefits of minimizing screen time are out of the scope of this article. I just want to talk about awesome adirondack-ness!

This whole set took us a week, a few hours a day or so. We built the exact same set we shared in this DIY Adirondack Set post, so you can find the plan there.

We changed the color scheme. I used Rustoleum Vintage Teal for the table. I found outdoor pillows at Walmart for $5 each that tied everything together!

Here is the first chair finished. Notice all the screw holes we had to fill before painting! I prefer Fast’N Final by DAP.

For the chairs and stools, I used Rustoleum Chalked in Linen White. It took 3 coats, which in my experiences is a lot for chalk paint. All in all, I am happy with the product and will use it again.

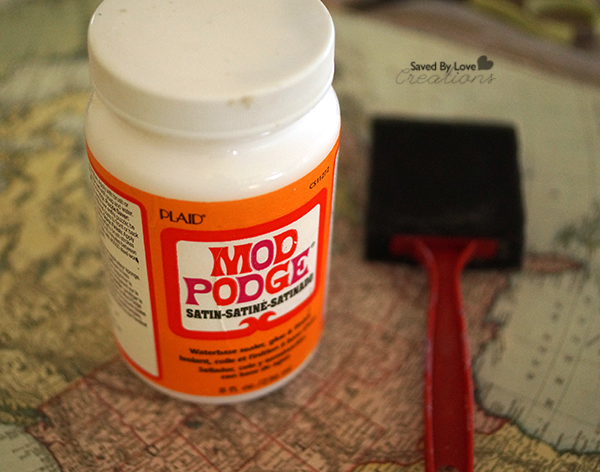

All five pieces were sealed with Minwax Polycrylic Water Based Protective Finish. It is my go to!

We love our new set, and our mornings spent together, present and peaceful!

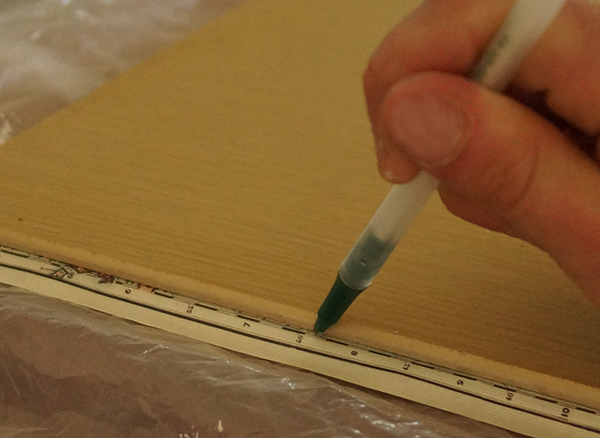

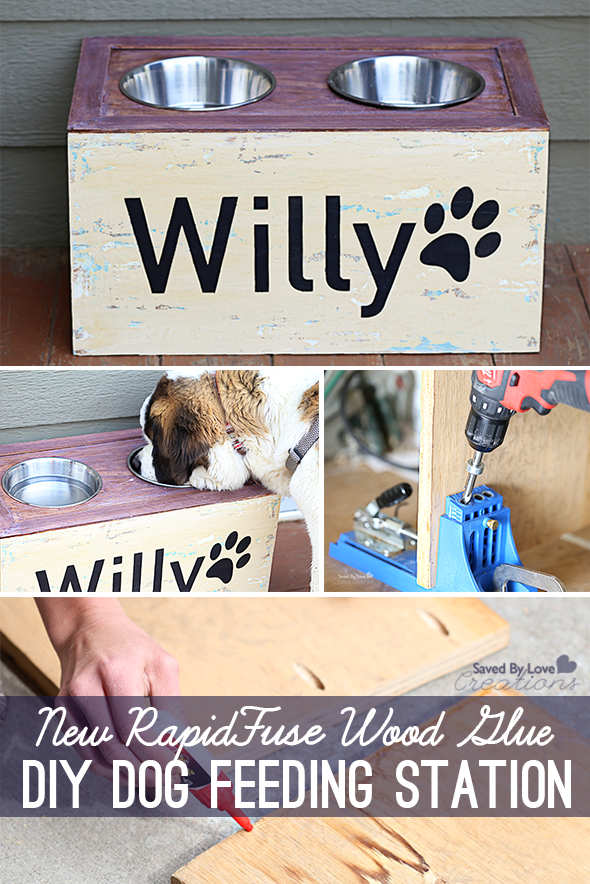

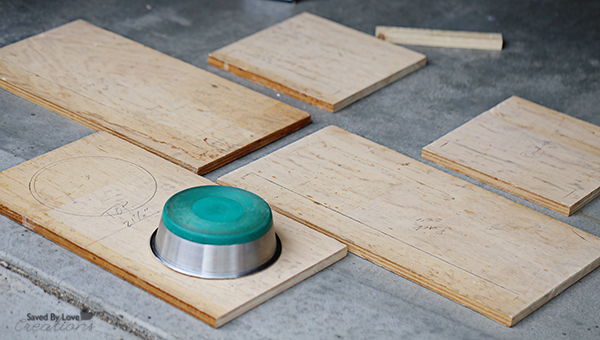

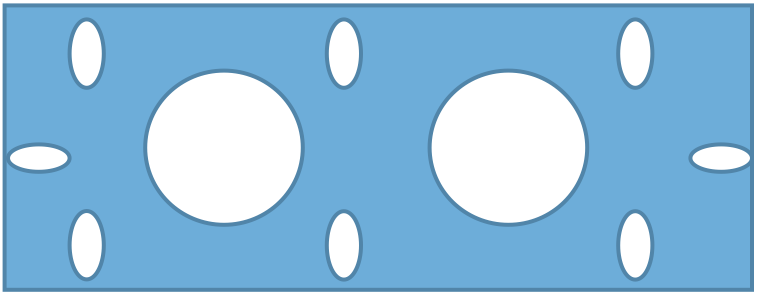

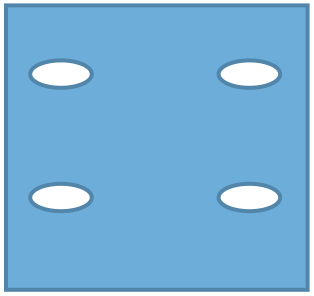

Get the bowl into position. For mine each bowl opening ended up being 3.25 inches apart in the center and 7.5 inches in diameter. You can set them however you want visually. Once in place, trace a line around the upside down bowls.

Get the bowl into position. For mine each bowl opening ended up being 3.25 inches apart in the center and 7.5 inches in diameter. You can set them however you want visually. Once in place, trace a line around the upside down bowls.

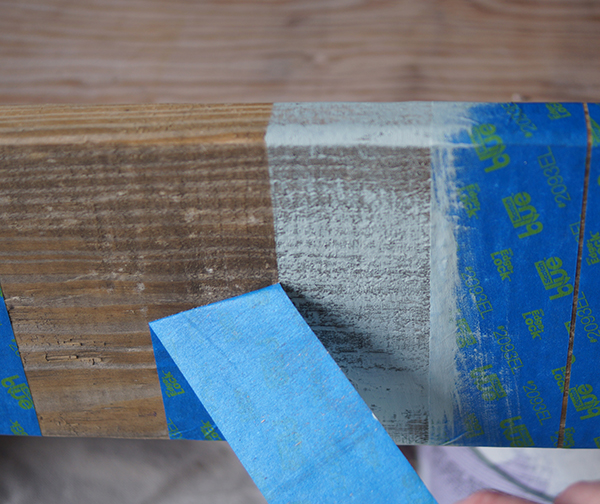

Before painting, sand any uneven areas.

Before painting, sand any uneven areas.