reclaimed wood projects

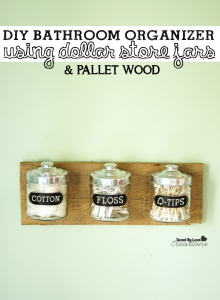

Dollar Tree Pallet Wood Bathroom Organizer Tutorial

April 29, 2014

Make a Stenciled Planter Box From Reclaimed Wood

March 28, 2014

Make a Repurposed Door TV Console

September 5, 2013

DIY Reclaimed Wood Headboard

August 28, 2013

How to Make a Chevron Table from Reclaimed Wood Pallet

August 21, 2013

DIY Wood Pallet Dog Feeder

July 29, 2013

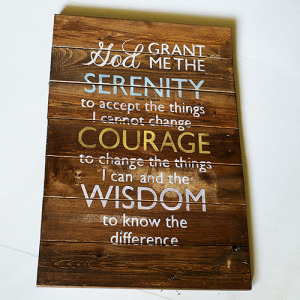

Easy Pallet Sign Using Kreg Jig

July 15, 2013

How to Resurface a Table with Reclaimed Wood

July 2, 2013